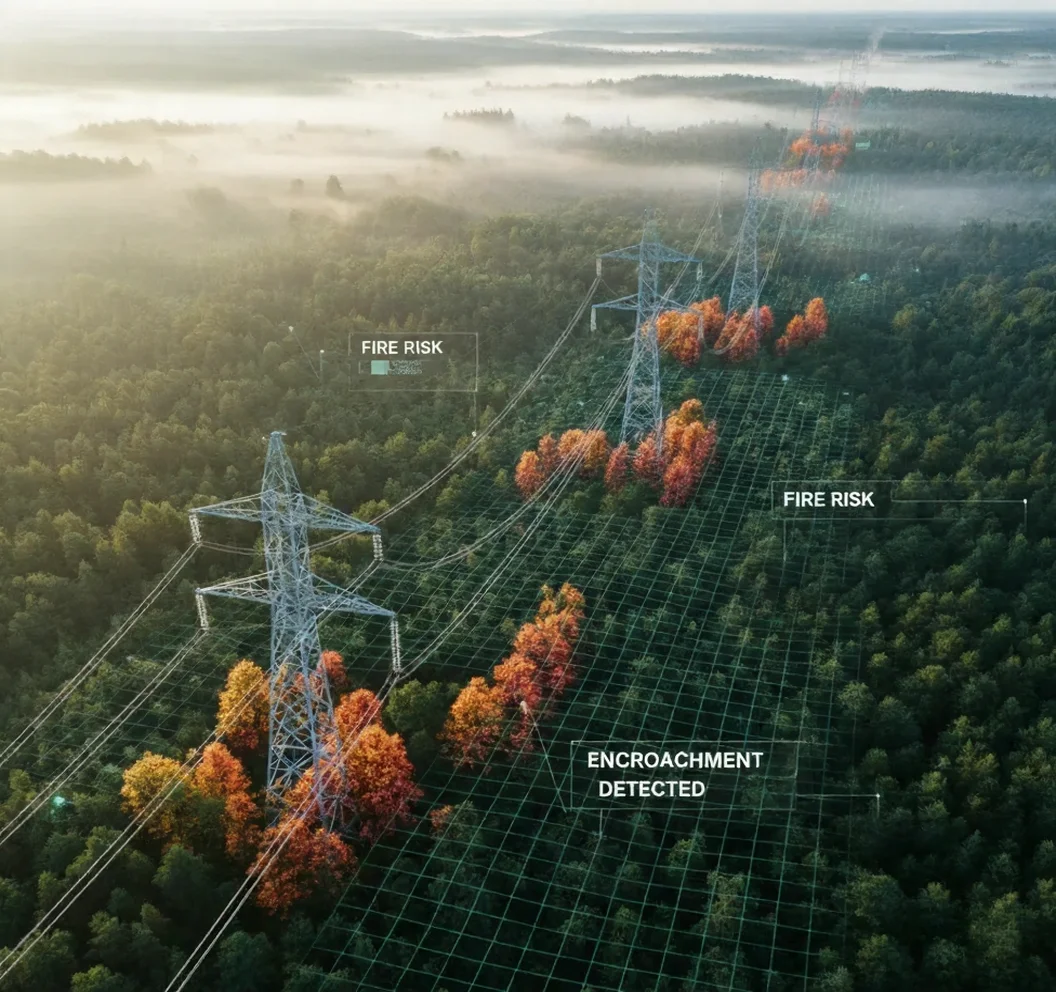

Unscheduled equipment breakdowns cause costly downtime in mining operations.

AssetGuard AI

Maximize Uptime, Minimize Costs

Overview

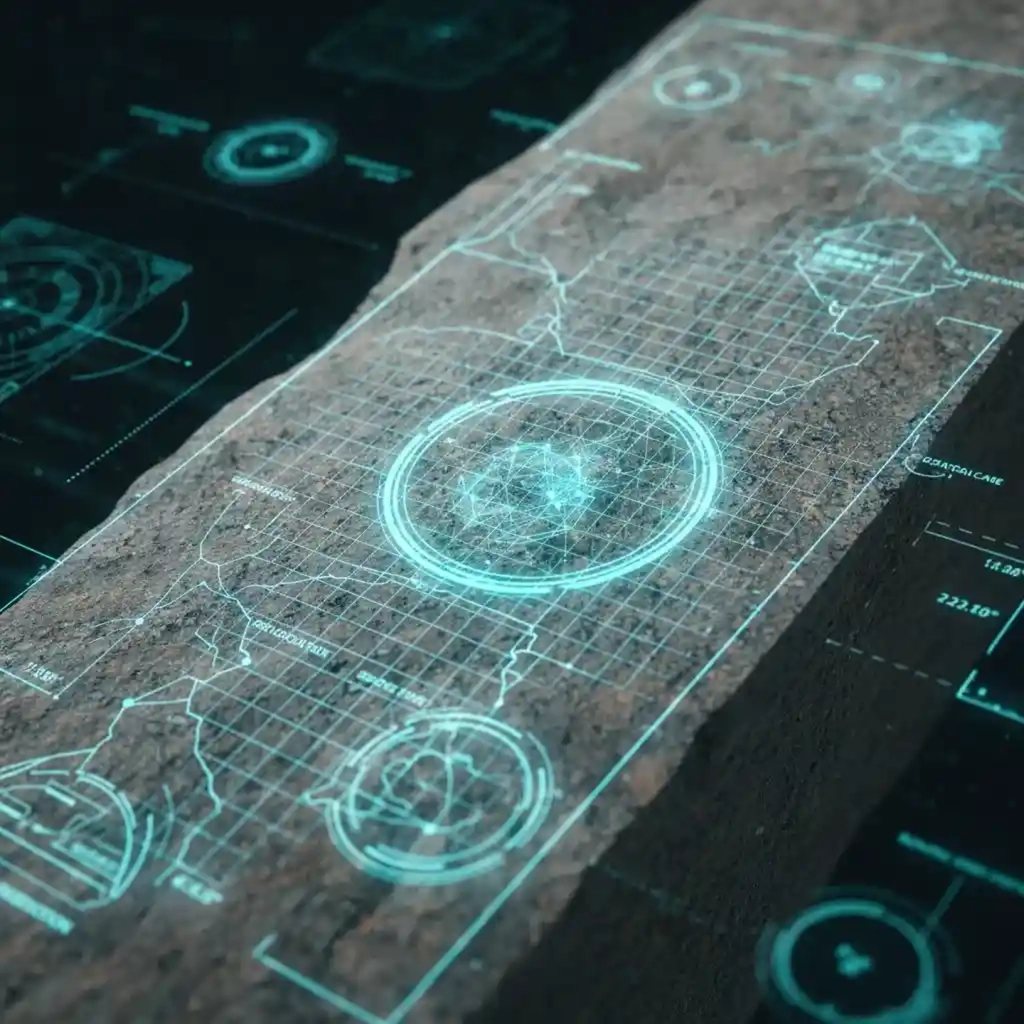

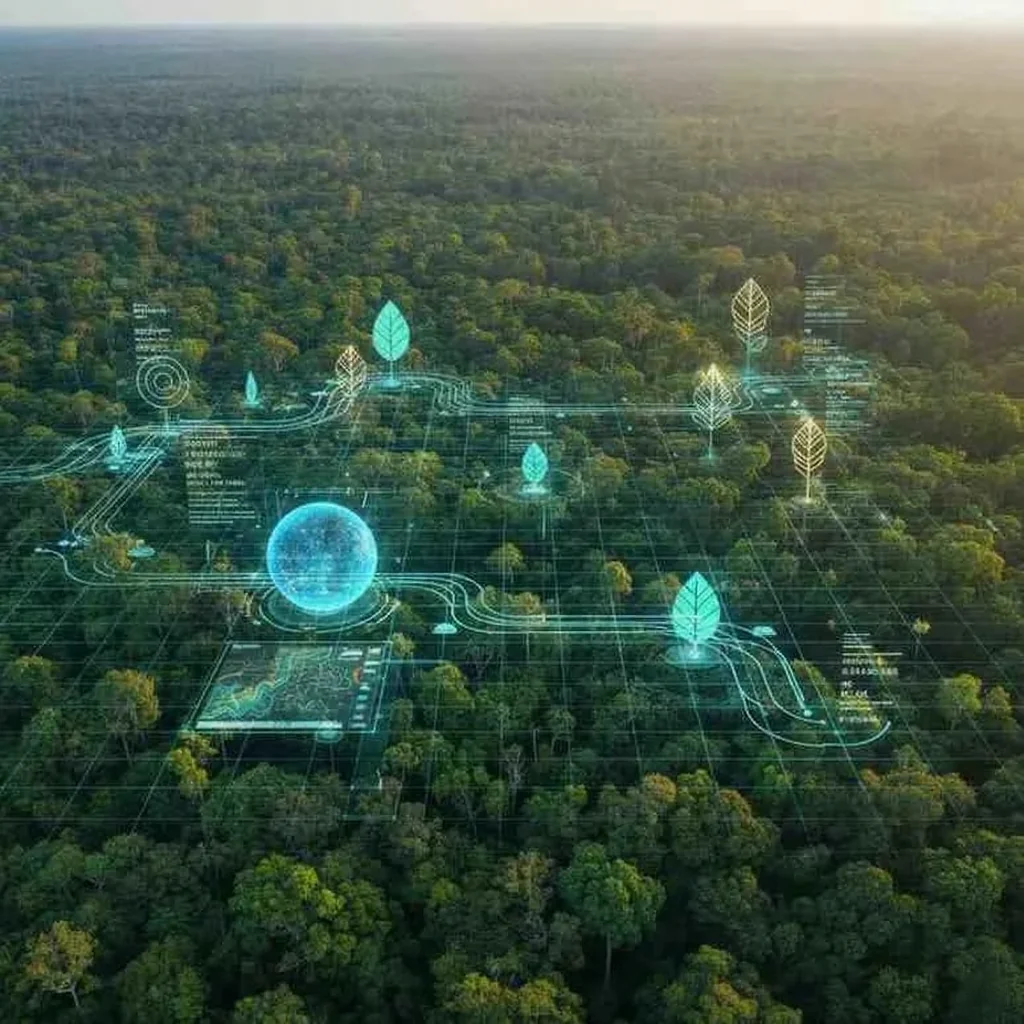

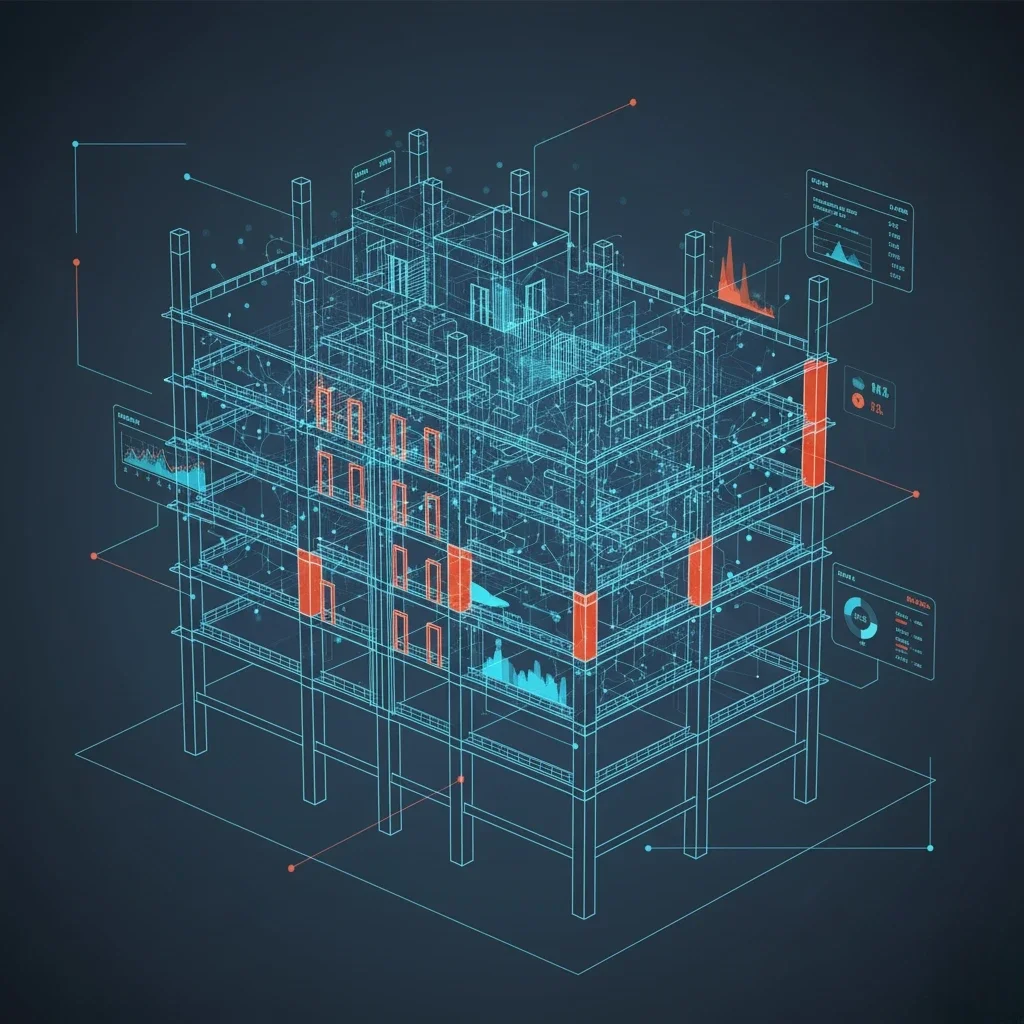

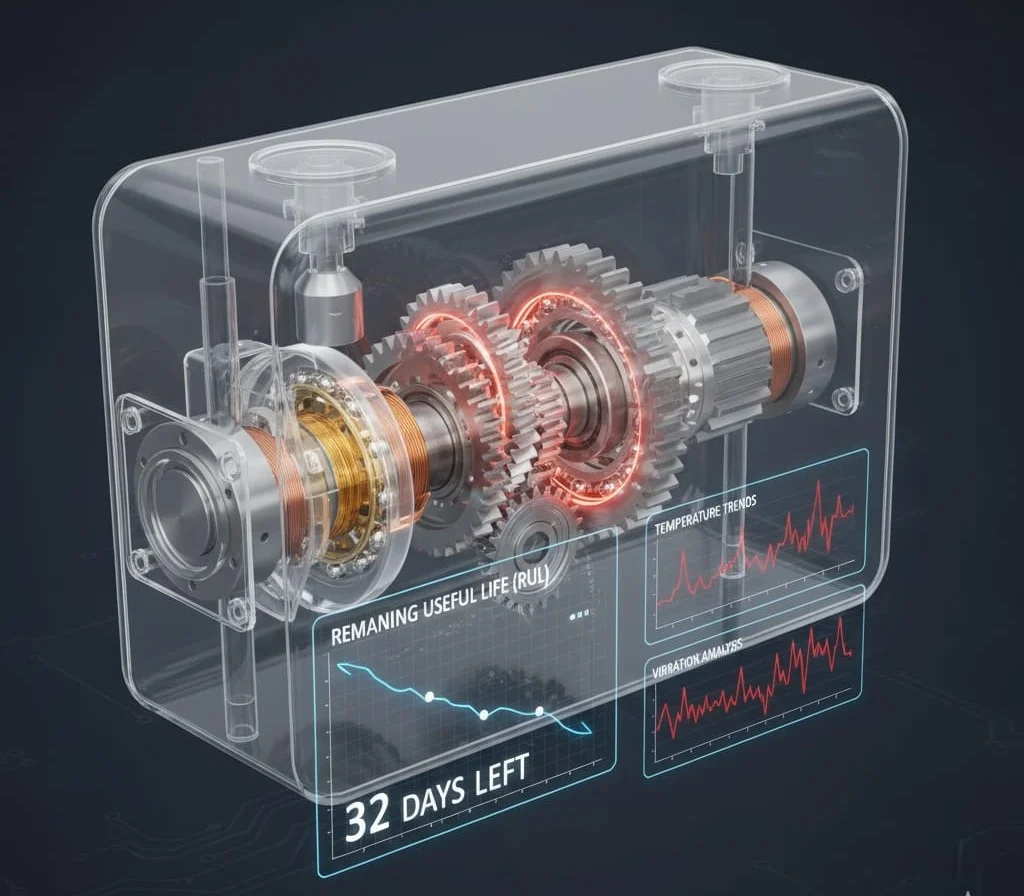

AssetGuard AI uses sensor and historical usage data to predict when machines will need servicing. Its machine learning models continuously analyze signals (vibration, temperature, pressure, oil quality, etc.) to detect early signs of component wear. Maintenance is scheduled just-in-time before failures occur, rather than on a fixed calendar. This proactive approach extends asset life and keeps production running smoothly, effectively transforming maintenance from reactive to data-driven.

Challenges

- Unexpected failures: Traditional schedules often miss real failure conditions, leading to emergency fixes.

- Costly downtime: Unplanned outages halt production and incur high emergency repair costs.

- Inefficient service: Fixed interval servicing can waste resources on unnecessary work.

Solution

- IoT sensors feed live condition data into AI models that forecast failures before they happen.

- Predictive alerts allow maintenance during planned downtime, avoiding unscheduled stops.

- Data-driven maintenance only when needed, focusing effort on genuinely at-risk equipment.

Key Features

How it works?

How is it used?

In a quarry, AssetGuard AI monitors a crushing mill. Rising vibration patterns on a bearing signal are recognized by the model, which predicts imminent failure. Two weeks notice is sent so the maintenance crew can replace the bearing during a weekend shutdown, preventing an unscheduled day-long breakdown during peak operations.

What impact is delivered?

Predictive maintenance significantly reduces downtime and costs. Case studies show that predictive systems can cut unplanned downtime by up to ~50% and lower overall maintenance costs by roughly 20–25%. This results in higher equipment availability and substantial savings in repair expenses. Extended equipment life and improved safety (fewer failing parts mean fewer accidents) are additional benefits.