Detect Leaks, Predict Maintenance, Minimize Downtime.

Pipeline Sentinel

AI-Driven Pipeline Integrity and Resilience

Overview

Pipeline Sentinel is an integrated AI platform that continuously analyzes sensor, SCADA, and inspection data to predict failures and monitor risk in real time. It fuses high-resolution flow, pressure, and acoustic sensor feeds with inspection and maintenance logs, using machine learning models and digital-twin simulations to identify anomalies and weak spots before they become critical. By leveraging APA’s existing SCADA and IoT networks, the system provides a clear, non-technical dashboard of pipeline health and risk scores, enabling proactive maintenance scheduling and emergency planning.

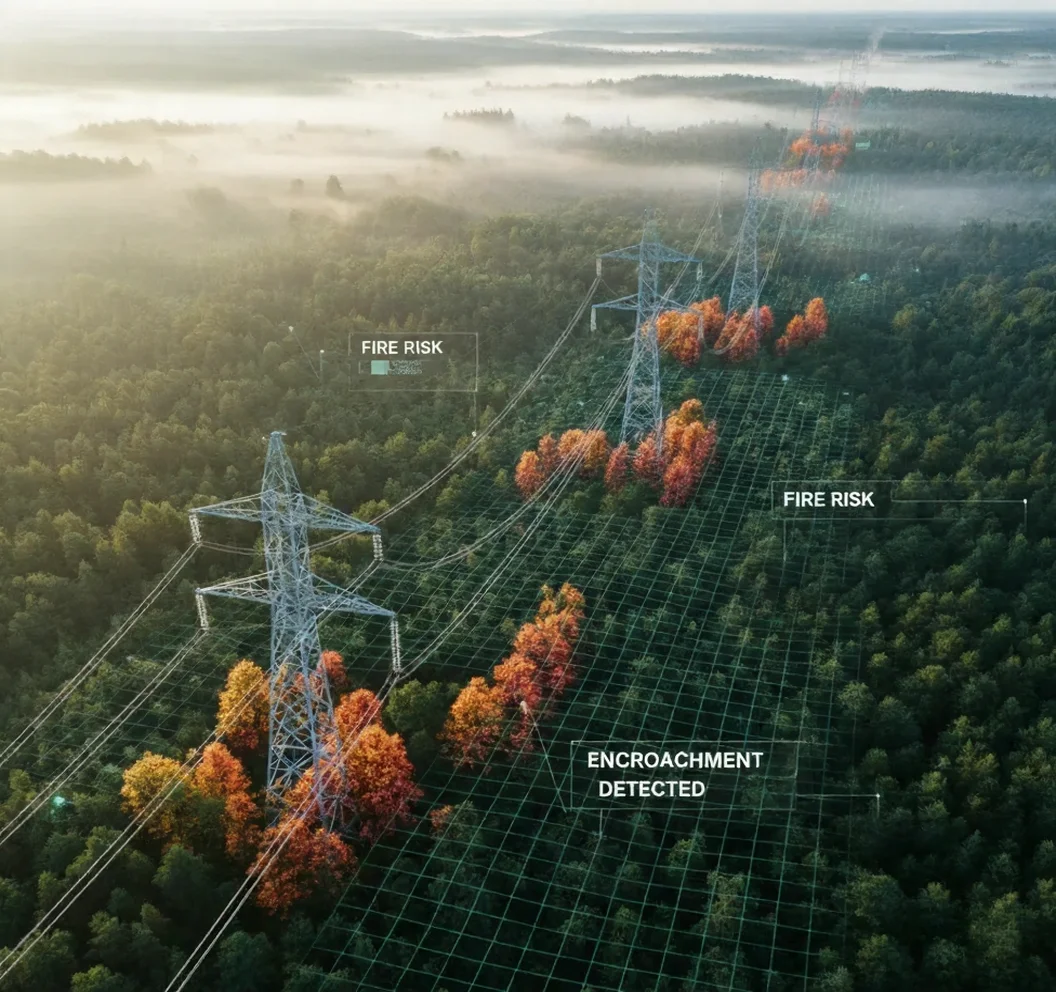

Pipeline Sentinel connects to pipeline SCADA and IoT sensors (pressure, flow, temperature, acoustic) and historical inspection data to build a real-time digital model of pipeline health. AI algorithms detect anomalies (leaks, pressure surges, corrosion) and predict failures, enabling operators to intervene early. This proactive approach aligns with APA’s priorities of safe operation and asset optimization. As one analysis notes, “predictive maintenance [enables] APA Group [to] anticipate equipment failures, minimizing downtime and costly emergency repairs.” By foreseeing issues, Pipeline Sentinel helps avoid spills or ruptures, optimize pipeline throughput, and extend asset life without unnecessary maintenance.

Challenges

- Gas pipelines operate under extreme pressure across long distances, where small faults (corrosion, leaks, equipment wear) can rapidly escalate into major safety and environmental incidents.

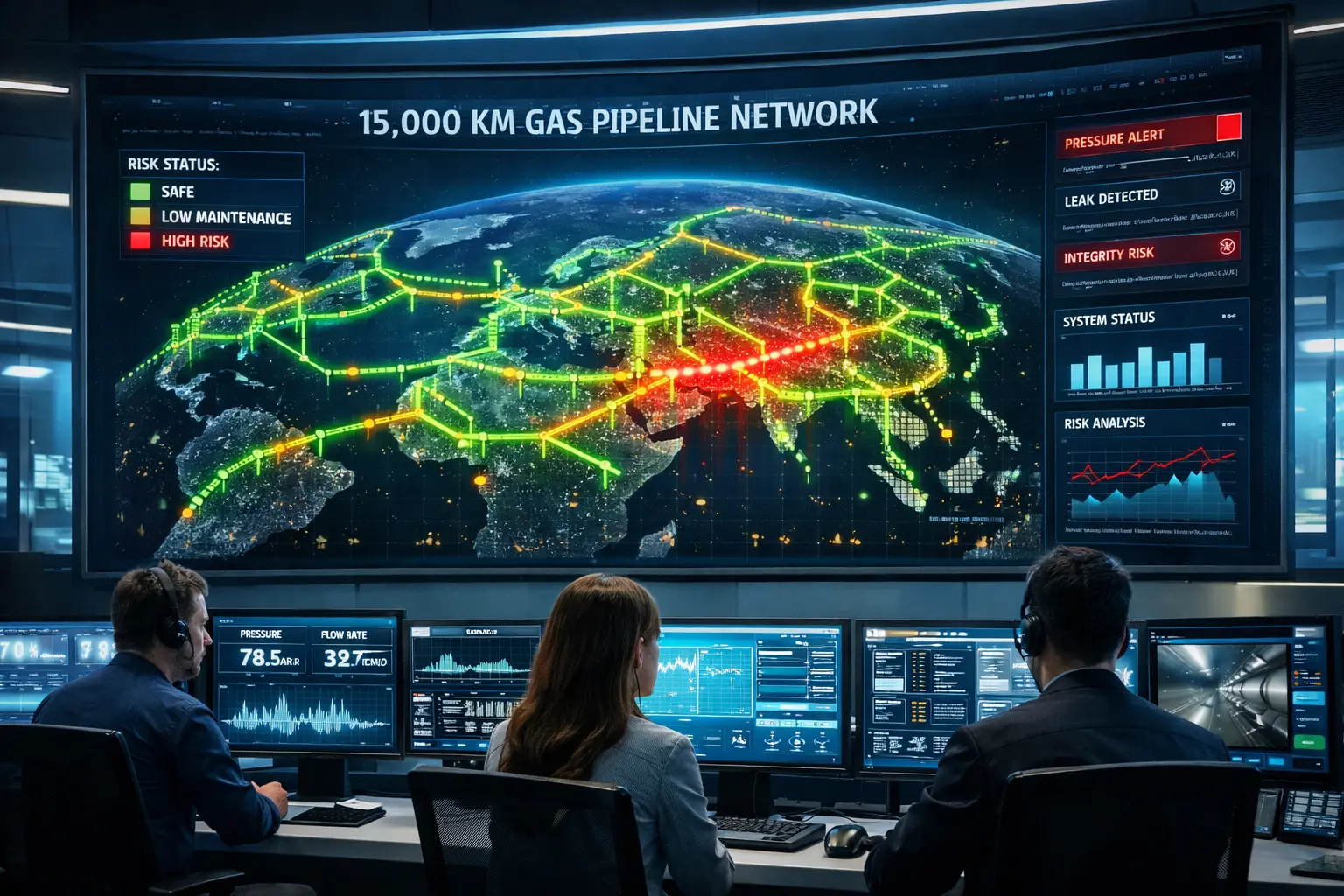

- Managing 15,000 km of pipelines makes it difficult to continuously monitor asset health using traditional, point-in-time inspections.

- Scheduled inspections and reactive repairs often miss early-stage issues and lead to unplanned downtime and costly emergency interventions.

- Legacy systems struggle to identify weak signals in noisy SCADA and sensor data, resulting in missed risks or excessive false alarms.

Failures expose operators to regulatory penalties, environmental damage, and significant operational and financial losses.

Solution

- Pipeline Sentinel ingests SCADA, IoT, and inspection data to maintain a live, end-to-end view of pipeline health across the entire network.

- AI models analyze multivariate sensor patterns to accurately detect leaks, pressure anomalies, and corrosion distinguishing true risks from normal fluctuations.

- Machine learning predicts equipment degradation and pipeline failures before they occur, enabling planned, low-impact maintenance.

- A real-time digital twin simulates pipeline behavior under different conditions, helping operators identify weak points and future risk scenarios.

- The platform converts complex data into clear risk scores and dashboards, allowing teams to focus inspections and repairs where they matter most reducing costs and improving safety.

Key Features

How it works?

AI Analytics

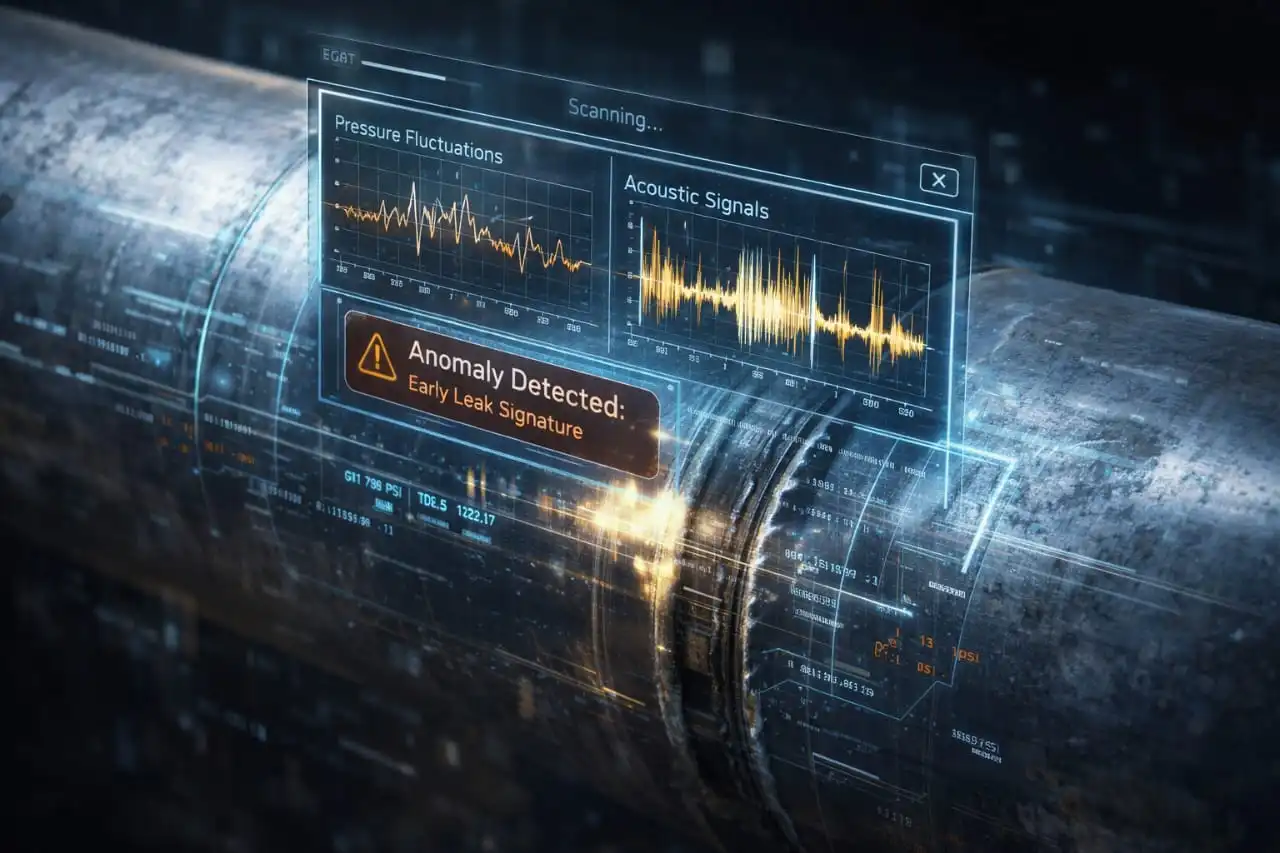

Machine learning models analyze this data in real time. For example, anomaly detection algorithms flag sudden pressure drops (possible leaks) or unusual flow patterns. Predictive models trained on past failure events estimate the remaining useful life of valves, compressors, and other assets. Advanced algorithms (e.g, deep learning) interpret sensor signatures to detect subtle corrosion or material fatigue.

Action & Feedback

Maintenance teams use these insights to inspect or repair proactively. After action, data (e.g. repair findings) are fed back into the system to continually improve model accuracy. Over time, the AI adapts to APA’s specific network behavior, reducing false positives and honing its predictions.

How Pipeline Sentinel Responds?

A remote section of high-pressure transmission pipeline shows a slight but consistent pressure drop detected by SCADA. Pipeline Sentinel anomaly detector flags this subtle change and cross-references it with acoustic sensor data, identifying a pattern consistent with developing corrosion. The AI assigns this section a high integrity risk score, sending a work order to inspect. Crews find a small leak and reinforce the pipe before any incident. Simultaneously, predictive models forecast that a compressor station’s cooling pump will likely need maintenance within 1000 operating hours; a scheduled shutdown is arranged to service it during low demand. In this way, the platform has pre-empted both an environmental incident and an unplanned outage.

What Value Is Delivered?

Early adopters of AI-driven pipeline analytics report significant safety and efficiency gains. For example, predictive maintenance can reduce failures by ~25% and cut maintenance costs by ~30%. Pipeline Sentinel helps APA minimize downtime (a critical metric where unplanned downtime in oil & gas costs ~$50B annually) by shifting to planned outages. By preventing even a single major leak, the system can save millions in cleanup, legal, and reputational costs. Continuous monitoring also increases asset availability and throughput, aligning with APA’s goals of resilience and cost-effective maintenance.

What Challenges Pipeline Sentinel Solves?

High-pressure gas pipelines and related infrastructure face critical safety and reliability challenges. Pipeline failures (due to corrosion, leaks, or equipment faults) can cause environmental harm, costly downtime, and regulatory penalties. APA Group, with 15,000 km of pipelines carrying half of Australia’s natural gas , must ensure safe operations, asset optimization, and cost-effective maintenance. Legacy approaches rely on scheduled inspections and reactive fixes, which struggle to catch subtle issues in vast networks.